Why Blade Quality Matters and How to Choose the Right Blades

When it comes to industrial shredding, precision and performance matter. Whether it’s wood, metal, plastic or any other kind of material, choosing the right quality blade for your machine is crucial to streamlining processes.

Buying blades requires balancing cost and quality, but opting for cheaper ones can lead to higher expenses over time.

This article highlights the importance of selecting the right blades and provides insights on maximising your investment. Plus, explore our helpful ROI tool to ensure you're getting the best value.

The Power of Shredding Efficiency

Speed isn’t the only factor that affects efficiency - it’s about quality, cost effectiveness and overall performance of your entire operation. An underperforming shredder can result in unnecessary downtime, higher energy consumption and lower quality output. Whether you are operating in waste management, recycling or manufacturing, efficient shredding is key to maximising profits and reducing operational costs.

3 Key Benefits of Improved Shredding Efficiency

-

Minimised Downtime – A well-maintained, high quality shredder experiences fewer breakages, reducing interruptions and the need for frequent blade replacements.

-

Lower Energy Consumption – High quality, precision engineered blades enhance energy efficiency, leading to significant cost savings.

-

Superior Output Quality – Sharp, durable blades ensure clean, consistent shredding, preventing material clogging and irregular cuts, minimising wastage.

By understanding these factors, you can see how choosing the right blades is essential for achieving optimal shredding performance and maximising your return on investment.

What Affects Shredding Efficiency?

Several factors influence the efficiency of your shredder, with blade selection being one of the most critical. Understanding these factors can help you optimise performance and extend the lifespan of your equipment.

Material Type

Different materials require specific blades for optimal performance. Soft materials like paper or textiles need different blades than tougher materials such as metal or wood. Choosing the right blade ensures smoother operation and longer blade life.

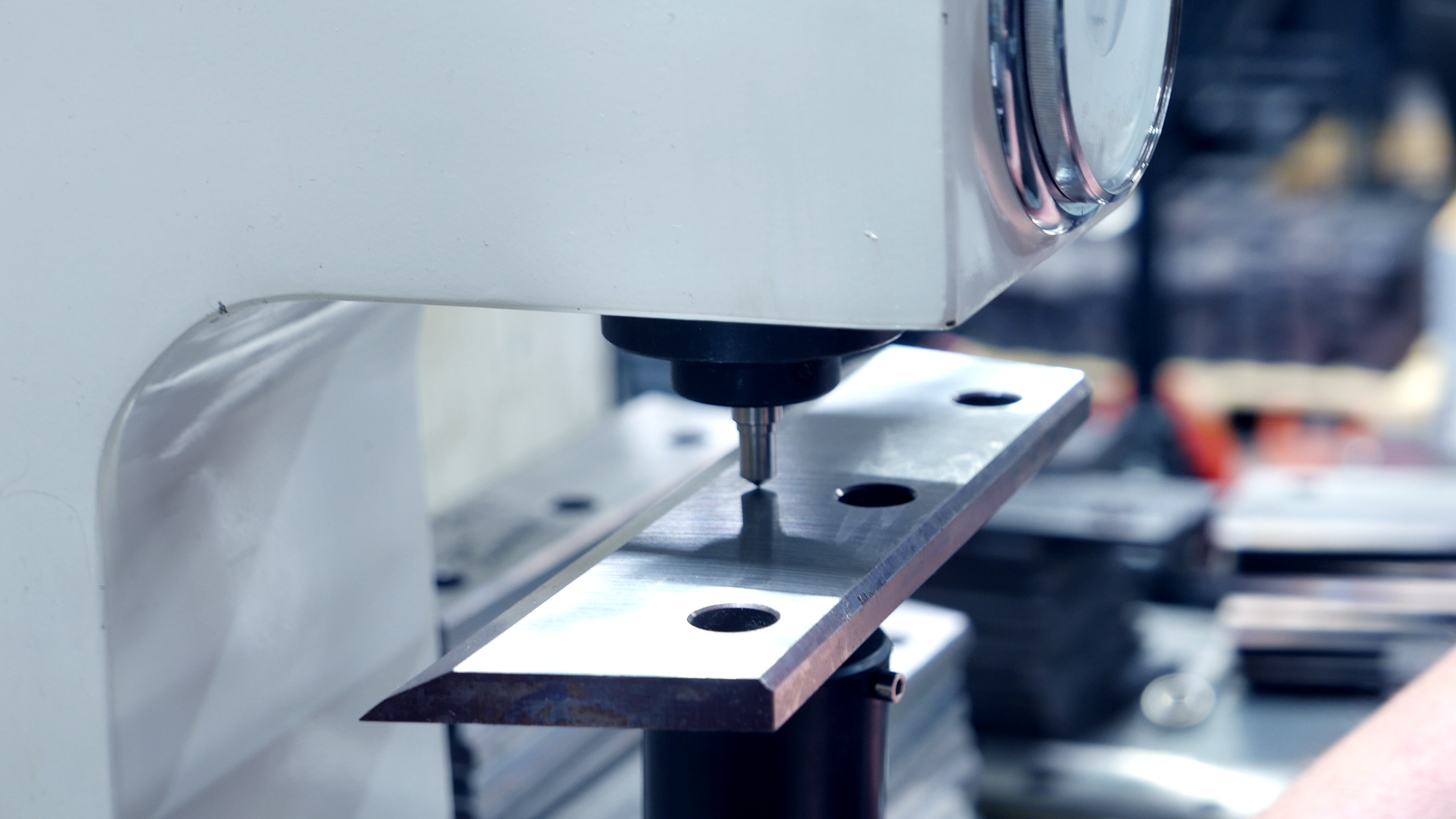

Blade Material

The composition of the blade affects its durability, sharpness, and overall performance. Options like alloy steel, high-carbon steel, and carbide-tipped blades offer varying levels of wear resistance and cutting precision. Selecting the appropriate material can enhance both efficiency and cost-effectiveness. A blade expert would be able to offer advice on material selection.

Blade Design

The design and configuration of the blade significantly impact shredding performance. Multi-shaft blades handle complex materials efficiently, while single-shaft blades are better suited for uniform materials. Custom fabrication with precision engineering ensures that your blade is the exact fit for your machine.

Choosing the right design is crucial, as it improves shredding consistency and reduces operational strain.

Shredder Machine Capacity

Your shredder’s capacity determines the type of blade required. High-capacity shredders demand stronger, more durable blades to withstand heavier workloads without compromising efficiency or longevity. Saturn Machine Knives manufacture durable blades designed to withstand tough materials.

Choosing the Right Blade

Selecting the right shredder blade requires careful consideration of several key factors. Follow this step-by-step guide to ensure optimal performance and cost-effectiveness.

Assess Your Shredding Needs

Identify the materials you process and the type of shredder you use. As previously discussed, different materials require different blade specifications to achieve efficient and effective shredding.

Understand Blade Materials

Choose a blade material that aligns with your operational demands. For example, if you're shredding tough materials like metal or rubber, carbide-tipped blades offer superior durability and cutting power.

Consider Blade Size and Design

Ensure the blade size and configuration are compatible with your shredder. Multi-shaft designs work well for complex materials, while single-shaft blades are better suited for uniform shredding tasks.

Talk to the Experts

Partner with a trusted blade supplier who understands your industry’s unique challenges and can recommend the most suitable blade for your application.

By selecting the right blade, you can maximise shredding efficiency, minimise your maintenance costs, and extend the lifespan of your equipment.

The Importance Of Blade Maintenance

Proper blade maintenance is key to keeping your shredder running efficiently and prolonging the lifespan of your equipment. Follow our essential maintenance practices:

1. Regular Sharpening

Keep blades sharp to reduce strain on the machine and maintain cutting precision. Dull blades increase energy consumption and decrease shredding efficiency.

2. Routine Cleaning

Remove debris and buildup from blades to ensure smooth operation and prevent blockages that can hinder performance.

3. Proper Alignment

Check blade alignment regularly to avoid uneven wear, minimize stress on the machine, and reduce the risk of jams.

4. Lubrication

Apply lubrication to moving parts to minimise friction, prevent overheating, and enhance overall durability.

By implementing these maintenance practices, you can extend your blade's life, optimise shredding efficiency, and reduce long-term operational costs.

Maximise Your Investment with Our ROI Calculator

Investing in the right shredder blades isn’t just about upfront costs - it’s about long-term savings and efficiency. Our ROI Calculator helps you determine the true value of your blade choices by analysing factors like blade lifespan and downtime. By inputting key operational data, you can see how different blades impact your bottom line, helping you make informed decisions that maximise performance and minimise expenses. Try our useful tool to ensure you’re getting the best return on your investment.

Optimise Your Shredder Blades for Maximum Efficiency

Selecting the right shredder blades and maintaining them properly can make a significant impact on your operation’s efficiency, cost-effectiveness, and overall performance. By understanding key factors such as material type, blade composition, and machine capacity, you can make informed decisions that enhance shredding productivity while reducing downtime and expenses.

Regular maintenance, including sharpening, cleaning, and proper alignment, ensures that your shredder operates at peak efficiency for longer. Additionally, leveraging tools like our ROI Calculator allows you to evaluate your investment and make the best choices for long-term profitability.

By prioritising high-quality blades over cheap material, and proactive maintenance such as blade sharpening, businesses can achieve smoother operations, improved output quality, and reduced operational costs - leading to a more sustainable and profitable shredding process.

Saturn Machine Knives are a leading UK manufacturer of machine knives. We can manufacture blades & knives to fit all machine makes and models. Find out how we can help you by getting in touch.